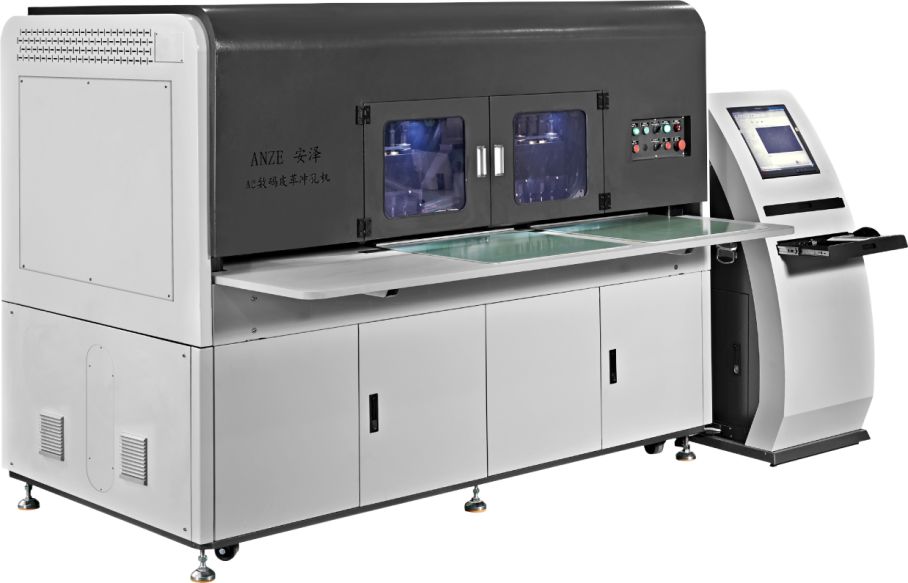

What issues should be noted when operating a CNC leather punching machine

The first step is to fill the oil tank with hydraulic oil, which usually requires about 120KG (note: it is recommended to use Great Wall brand hydraulic oil)

Step 2: Install the mold (note that when installing the mold, it must be installed vertically and horizontally, and the punch head and the outer mold frame needle should be dragged smoothly when retracted)

Step 3: Connect the power supply (note that the main power supply is 380V, and the power can only be turned on after ensuring that it is correct in both forward and reverse directions)

The CNC profile punching machine should be idle for 2-3 minutes before operation, to check the flexibility of the foot brake and other control equipment, and confirm that it is normal before use. It is not allowed to operate with defects. The mold should be sturdy, with the upper and lower molds aligned to ensure correct orientation. The machine tool should be manually rotated for trial punching (empty) to ensure that the mold is in excellent working condition. Before driving, pay attention to smoothness and remove all floating items from the bed surface.

During the operation of punching or punching, the operator should stand appropriately, maintain a certain distance between their hands and head and the punching machine, and pay attention to the movement of the punch at all times. It is strictly prohibited to chat with others. When punching or making small workpieces, specialized tools should be used and direct feeding or picking of materials by hand is not allowed.

When operating a stainless steel punching machine, it is important to remember not to wear gloves with loose threads, as CNC fully active punching machines are high-speed mechanical equipment. Gloves with loose threads may get tangled into the equipment to avoid irreparable harm to the human body. During the operation of other stainless steel punching machines, some wires and ropes should not appear in the operating area, so as to better prevent accidents during work.

When operating the machine, if you need to adjust the speed, stroke, clamp things and workpieces, or clean the equipment, you must pause the operation. Special keys should be used when installing and unloading drill bits, and hammers should not be used indiscriminately to prevent deformation of the central connecting shaft.

In order to prolong the lifespan of the equipment, it is important to pay attention to maintenance in daily life. After finishing work every day, remember to turn off the power and clean it with a cloth. It is also necessary to regularly maintain important parts of the stainless steel punching machine. If any abnormalities are found in the CNC active punching machine, it is necessary to check and repair it in a timely manner. Do not operate the equipment when it is faulty. After closing the main switch, the machine tool should be wiped clean, the work site should be cleaned, and the components should be checked for normal operation when starting the machinery every day.

Article source: Jiangmen Leather Punching Machinehttp://www.hslichuang.com/

-

10-14

Leather cutting machine: How to choose fiber laser cutting machine

When choosing a fiber laser cutting machine, it is important to check the cutting precision, which can generally be controlled between 0.1 millimeters and 0.2 millimeters. In the process of actual inc

-

10-13

Leather cutting machine: the influence of cutting oxygen pressure on cutting speed

When using CNC flame cutting machine, there are many factors that affect the gas flame cutting process, among which cutting oxygen flow plays a crucial role in gas flame cutting. Cutting open the oxyg

-

10-12

Leather cutting machine: Characteristics of leather cutting machine

Characteristics of leather cutting machineThere are still many manufacturers on the market who make leather cutting machines. So, among the many manufacturers, how to choose a suitable equipment manuf

-

10-11

Digital leather punching tells you the characteristics of CNC punching machines

The operation and monitoring of the CNC punching machine are all completed in this CNC unit, which is the brain of the CNC punching machine. Compared with ordinary punching machines, CNC punching mach

National Service Hotline

National Service Hotline