What issues should be noted during the use of a digital leather punching machine?

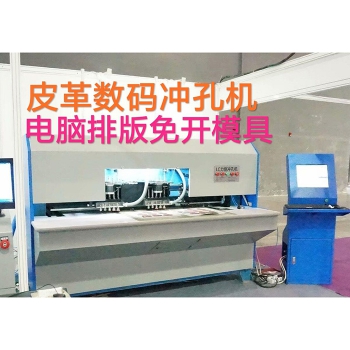

High quality digital leather punching machines play an important role in various industries, and due to their remote operation, they are more suitable for use in many fully enclosed processing workshops. Although digital leather punching machines are also cost-effective equipment among punching machines, special attention should be paid during use. So what issues should be paid attention to when using a digital leather punching machine?

1. Wear rubber gloves during maintenance

The digital leather punching machine is composed of parts that use hydraulic, backup power, and pneumatic control, such as automatic tool changing device, exchange worktable device, fixture, and transmission device. Therefore, even after power failure, it may be charged or even start on its own in special circumstances. If the drill bit on the glove is entangled due to the high-speed operation of the yarn on the glove, which can pierce the steel plate, the consequences are unimaginable. Therefore, rubber gloves must be matched during maintenance to avoid accidental power generation and static electricity.

2. Maintenance must be carried out in a stopped state

Due to its strong performance, the high-speed rotating equipment of the digital leather punching machine can cause irreparable losses to the operator if accidentally touched during operation. When operating the digital leather punching machine itself and replacing processing materials, it is necessary to strictly follow the instructions in the operating manual, stop and then power off before proceeding with the operation.

3. Pay attention to regular cleaning and maintenance in daily life

In order to prolong the lifespan of the digital leather punching machine, it is important to pay attention to maintenance in daily life. After work, remember to turn off the power. Some special components cannot be wiped directly with water or tap water, and need to be cleaned with specialized cleaning agents and cloths. If the digital leather punching machine is found to be blocked or has abnormal noise during operation, pay attention to checking for foreign objects in the gaps.

Although digital leather punching machines with high cost-effectiveness are not expensive, caution should still be exercised when using the equipment. Especially when starting the digital leather punching machine every day, it needs to be inspected by professionally trained maintenance personnel. Only when everything is normal can the day's work begin, ensuring the safety and efficiency of the work.

The article comes from a digital leather punching machine:http://www.hslichuang.com/

-

10-14

Leather cutting machine: How to choose fiber laser cutting machine

When choosing a fiber laser cutting machine, it is important to check the cutting precision, which can generally be controlled between 0.1 millimeters and 0.2 millimeters. In the process of actual inc

-

10-13

Leather cutting machine: the influence of cutting oxygen pressure on cutting speed

When using CNC flame cutting machine, there are many factors that affect the gas flame cutting process, among which cutting oxygen flow plays a crucial role in gas flame cutting. Cutting open the oxyg

-

10-12

Leather cutting machine: Characteristics of leather cutting machine

Characteristics of leather cutting machineThere are still many manufacturers on the market who make leather cutting machines. So, among the many manufacturers, how to choose a suitable equipment manuf

-

10-11

Digital leather punching tells you the characteristics of CNC punching machines

The operation and monitoring of the CNC punching machine are all completed in this CNC unit, which is the brain of the CNC punching machine. Compared with ordinary punching machines, CNC punching mach

National Service Hotline

National Service Hotline