How is the punching needle processed

Punching needles are also known as sharp mouth punches, round punches, punch heads, etc. Knife die hardware accessories, punching needles, leather punching special punches, leather punching special molds, edge cutting holes, double-sided punching, digital punching special punches, EVA punching, there are so many classifications. How is the punching needle processed? Let's take a look at the general manufacturing process of punching needles with the editor below.

1. Car breakage

After passing the laboratory test, the raw materials are drawn into the required diameter scale by a wire drawing machine, and then cut into fixed length rod-shaped punch blanks.

2. Knife edges at both ends of the car

Before heat treatment, the needle blank material is first straightened on a straightening platform using a dial gauge. Then, it is placed in a high-frequency electric furnace or salt bath furnace and heated to 800-1300 degrees Celsius for 2-5 minutes. After oil cold quenching and precision quenching heat treatment, the needle tip hardness can reach Hv590-800. Finally, low-temperature tempering treatment is carried out.

3. Wash two slanted holes

Clamp the punching needle onto the spring clamp of the machine tool, and perform grinding and forming processing according to the viewpoint and scale requirements of various pointed bases of the punching needle.

4. Grinding the wool thread

Polishing is the process of cleaning the surface of oil stains, rust, and other contaminants to achieve a clean finish.

5. Heat treatment

Inspect according to the required target index, and ship qualified products with rust proof oil in tight bags.

Article source: Jiangmen Leather Punching Machinehttp://www.hslichuang.com/

-

10-14

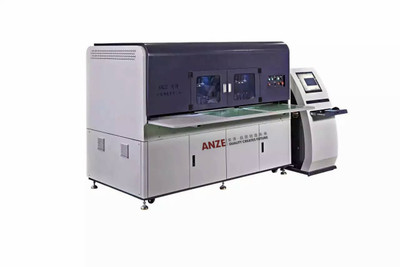

Leather cutting machine: How to choose fiber laser cutting machine

When choosing a fiber laser cutting machine, it is important to check the cutting precision, which can generally be controlled between 0.1 millimeters and 0.2 millimeters. In the process of actual inc

-

10-13

Leather cutting machine: the influence of cutting oxygen pressure on cutting speed

When using CNC flame cutting machine, there are many factors that affect the gas flame cutting process, among which cutting oxygen flow plays a crucial role in gas flame cutting. Cutting open the oxyg

-

10-12

Leather cutting machine: Characteristics of leather cutting machine

Characteristics of leather cutting machineThere are still many manufacturers on the market who make leather cutting machines. So, among the many manufacturers, how to choose a suitable equipment manuf

-

10-11

Digital leather punching tells you the characteristics of CNC punching machines

The operation and monitoring of the CNC punching machine are all completed in this CNC unit, which is the brain of the CNC punching machine. Compared with ordinary punching machines, CNC punching mach

National Service Hotline

National Service Hotline