How to maintain leather punching machine

The maintenance of primary leather punching machines can greatly delay the rate of accuracy decline. The decline in accuracy of leather punching machines is mainly manifested in two aspects: wear and plastic deformation of the parts. Due to the wear and deformation of the parts, the motion relationship (time and movement) between the parts is destroyed, resulting in a decrease in accuracy of the leather punching machine. Practical experience has proven that leather punching machines that are not maintained or improperly maintained have a much faster rate of accuracy decline than those that are well maintained.

Secondly, excellent maintenance of leather punching machines can improve their usage rate. In addition to normal factors, the decrease in accuracy of leather punching machines is also related to many critical factors, such as machine operation with problems and poor maintenance. Leather punching machines with poor maintenance have a greater impact on accuracy, and therefore have to frequently shut down for repairs, which affects production.

In addition, excellent maintenance of leather punching machines can extend their lifespan. Wear and deformation of leather punching machine components are inevitable, and the purpose of leather punching machine maintenance is to keep the machine accuracy in a normal state of loss, and to prolong this process as much as possible.

The importance of maintenance determines that the maintenance of ultrasonic machines is an important mission in daily equipment management. The completion of this mission is a human element. If human subjective initiative is not fully utilized, it is obviously impossible to maintain existing mechanical equipment. We need to understand the importance of maintenance with a scientific attitude, respect science, and trust science. Let's talk about the maintenance of leather punching machines from these aspects

Strengthen the management of operators. The uneven quality of operators determines the uneven maintenance quality of leather punching machines, so the first priority is to improve the skill level of operators, who possess such knowledge. To have a basic understanding of the structure of leather punching machines and a deep understanding of daily maintenance, it is necessary to understand why leather punching machine maintenance is necessary. To understand the essential causes of some mechanical failures, strict pre job training should be provided to employees. Newly employed employees should do more work on leather punching machine maintenance.

(1) Establish strict implementation systems, reward diligence and punish laziness. As leather punching machine maintenance is a complex task that requires patience and detail, it cannot be done hastily. Without strict rules and regulations, machine maintenance is impossible.

(2) Strengthening the importance of maintenance education: Leather punching machine maintenance is a daily task that employees must do, which can easily cause them to feel irritable. Therefore, it is necessary to strengthen education for employees, so that they can remember the importance of this issue in their hearts and reflect it in their daily operations. In addition to educating operators on the importance of strengthening maintenance, it is also necessary to strengthen the education of management personnel in this area. In this regard, it is necessary to avoid interference from outsiders with experts and to eliminate the use of rigid equipment.

Adopt scientific methods and strengthen machine maintenance. It is necessary to adopt scientific methods for maintaining leather punching machines, so as to ensure the maintenance of super leather punching machines. Therefore, it is necessary to use all available conditions to improve employees' scientific maintenance awareness.

(1) It is necessary to establish rules and regulations for the maintenance of leather punching machines. Generally, the maintenance of leather punching machines should be based on the machine manual. Regularly refueling, cleaning filters, testing the accuracy of ultrasonic machines and leather punching machines to determine the components for minor and medium repairs. These regulations should be posted around the leather punching machine to frequently remind operators.

(2) Strengthening the maintenance of key components such as gears, screws, sprockets, bearings, and other heavier mechanical parts, changes in their accuracy mean changes in production quality. Of course, it does not mean that other components can be lowered due to changes in their accuracy. Of course, it does not mean that the maintenance requirements for other components can be reduced.

(3) Carry out skill transformation and strengthen the maintenance of leather punching machines. Due to the fact that the design of leather punching machines must not have any conflicts or interferences in terms of circuits and machinery, especially for ultrasonic waves, improvements or remedial measures should be taken for structures that are originally conducive to the maintenance of leather punching machines.

In short, maintenance of leather punching machines should be carried out from the date of machine installation until the leather punching machine is scrapped and stopped.

Article source: Leather punching machine manufacturerhttp://www.hslichuang.com/

_ueditor_page_break_tag_-

10-14

Leather cutting machine: How to choose fiber laser cutting machine

When choosing a fiber laser cutting machine, it is important to check the cutting precision, which can generally be controlled between 0.1 millimeters and 0.2 millimeters. In the process of actual inc

-

10-13

Leather cutting machine: the influence of cutting oxygen pressure on cutting speed

When using CNC flame cutting machine, there are many factors that affect the gas flame cutting process, among which cutting oxygen flow plays a crucial role in gas flame cutting. Cutting open the oxyg

-

10-12

Leather cutting machine: Characteristics of leather cutting machine

Characteristics of leather cutting machineThere are still many manufacturers on the market who make leather cutting machines. So, among the many manufacturers, how to choose a suitable equipment manuf

-

10-11

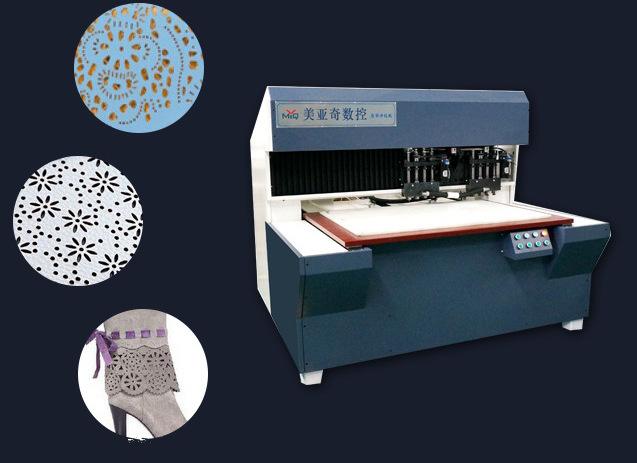

Digital leather punching tells you the characteristics of CNC punching machines

The operation and monitoring of the CNC punching machine are all completed in this CNC unit, which is the brain of the CNC punching machine. Compared with ordinary punching machines, CNC punching mach

National Service Hotline

National Service Hotline